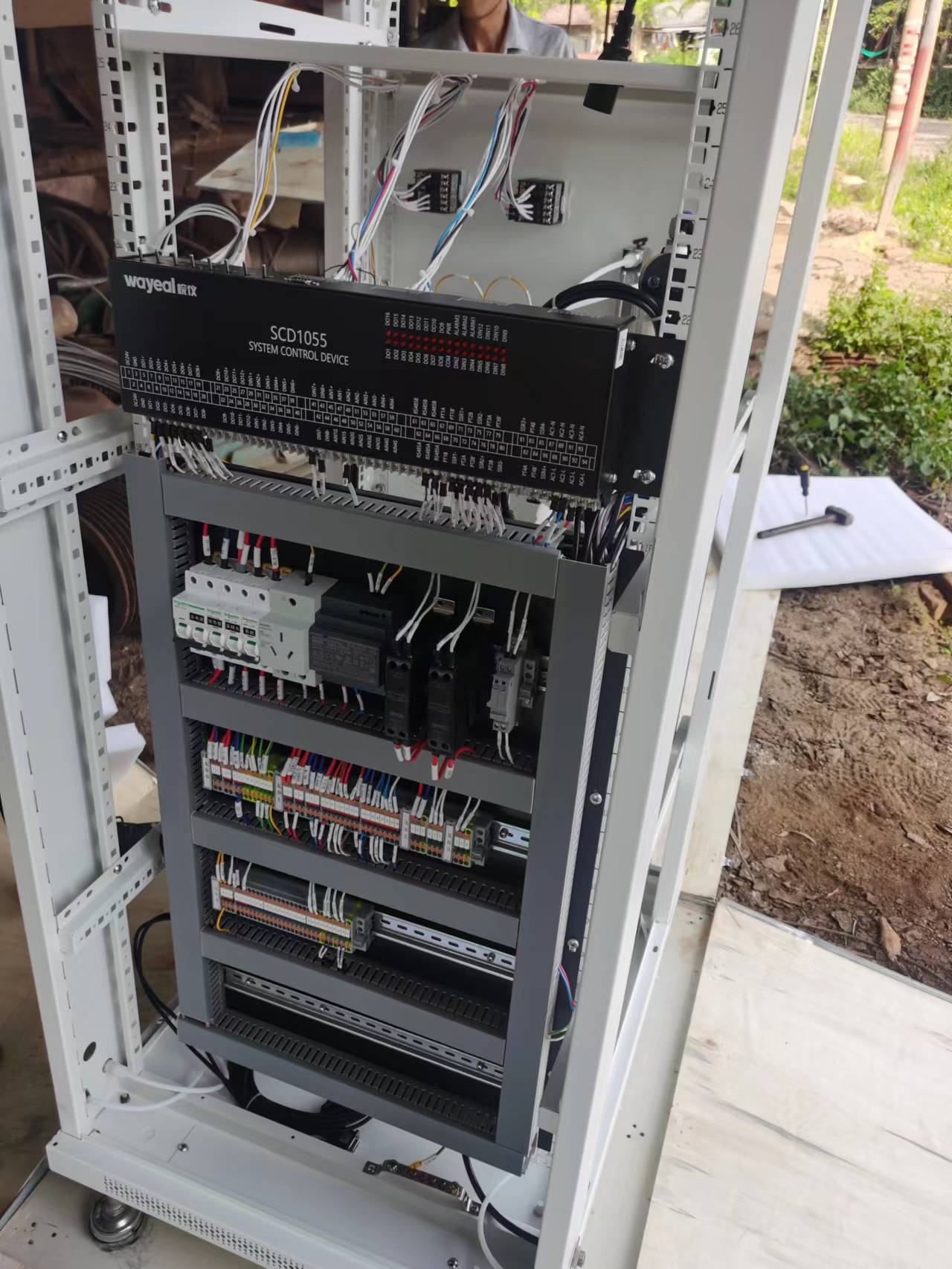

This online flue gas monitoring device CEMS1300 type flue gas emission continuous monitoring system can continuously monitor many related parameters such as SO2, NO, O2, flue gas concentration, flue gas temperature, pressure, flow rate, humidity, etc., and count the emission rate, total emission, etc. So as to effectively manage the data.

CEMS1300 system consists of four subsystems: monitoring of gaseous pollutants (SO2, NO, O2, etc.), monitoring of flue gas parameters (temperature, pressure, flow rate, humidity, etc.), and data acquisition and processing. The monitoring of gaseous pollutants is to measure the content of SO2 and NO in flue gas by ultraviolet difference method; The O2 content is measured by electrochemical method; The temperature of flue gas is measured by temperature sensor; The flue gas pressure is measured by pressure sensor; The flue gas velocity is measured by pitot tube; The flue gas humidity is measured by high temperature capacitive humidity sensor, and all measured signals are sent to the data acquisition and processing system. The output processing system has the functions of real-time transmission of field data, remote fault diagnosis, report statistics and graphic data analysis, and realizes unattended operation at the work site. The whole system has simple structure, wide dynamic range, strong real-time, flexible networking and low operating cost. At the same time, the system adopts modular structure, which is easy to combine. It can be flexibly optimized according to the specific working condition parameters and technical requirements of the site, fully meeting the needs of users, and ensuring the best cost performance of the system. The system can fully meet the communication requirements with the internal DCS system of the enterprise and the data system of the environmental protection department.